Stock SizesNeed A Specific Size? Contact Us For A Quote

Standard FeaturesDo You Need A Unique Feature? Tell Us What You Need

AWS Welding

Standards

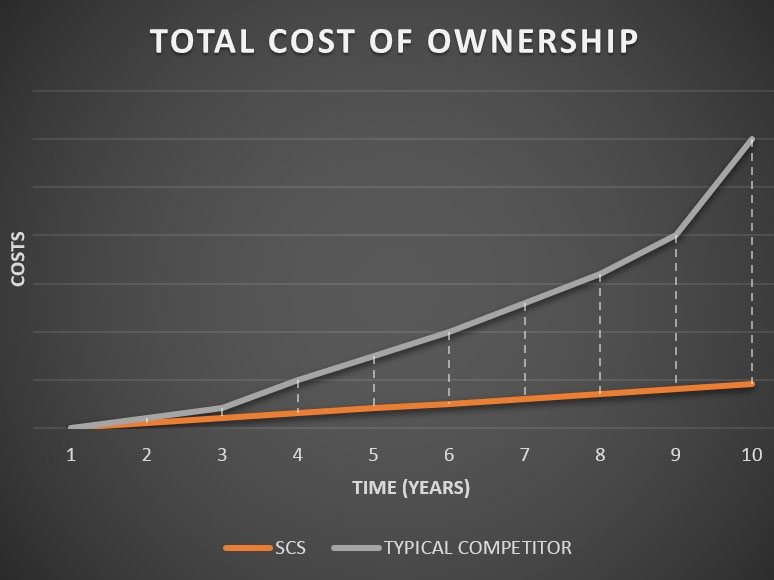

Our AWS welding procedures guarantee exceptional weld quality. Eliminate breakdowns and reduce the overall life-cycle maintenance costs.

Manufactured Above Industry Standard

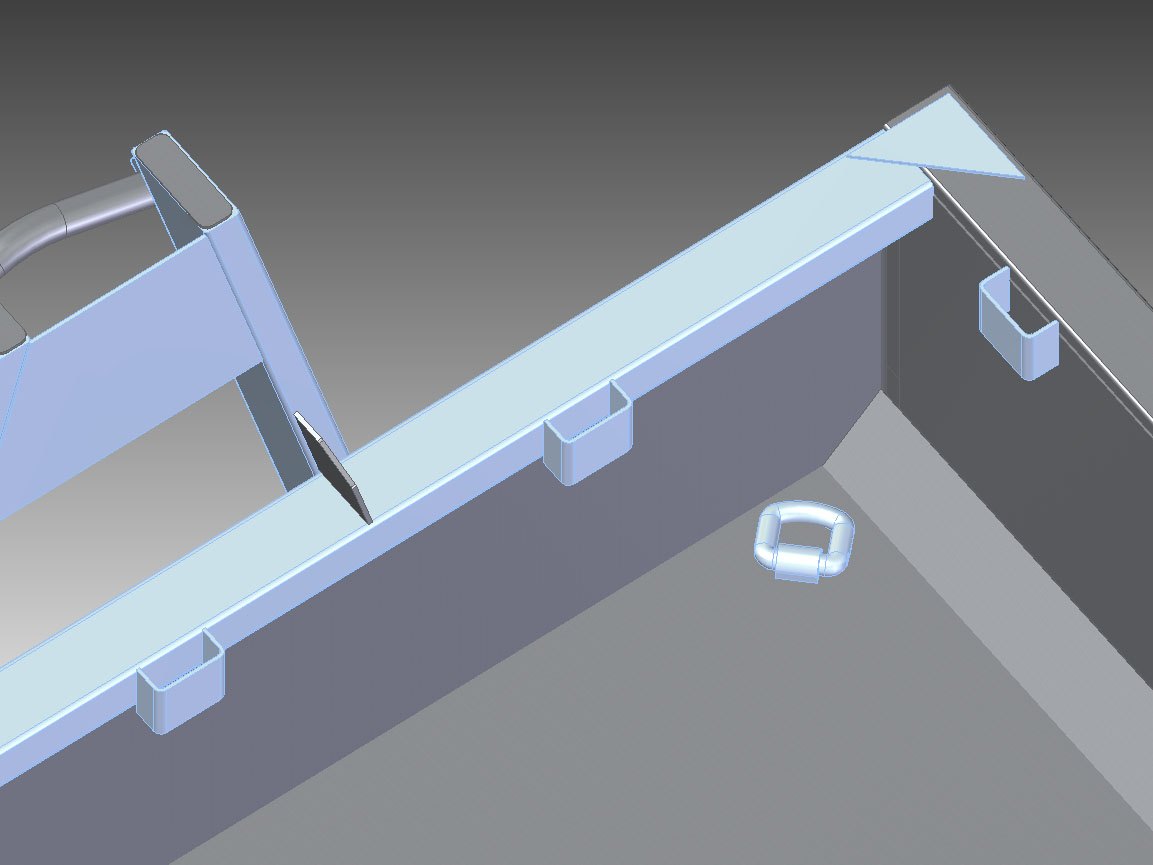

SCS contractor duty roll offs have inside & outside wall supports(skirts); and the same number of wall studs as floor cross members.

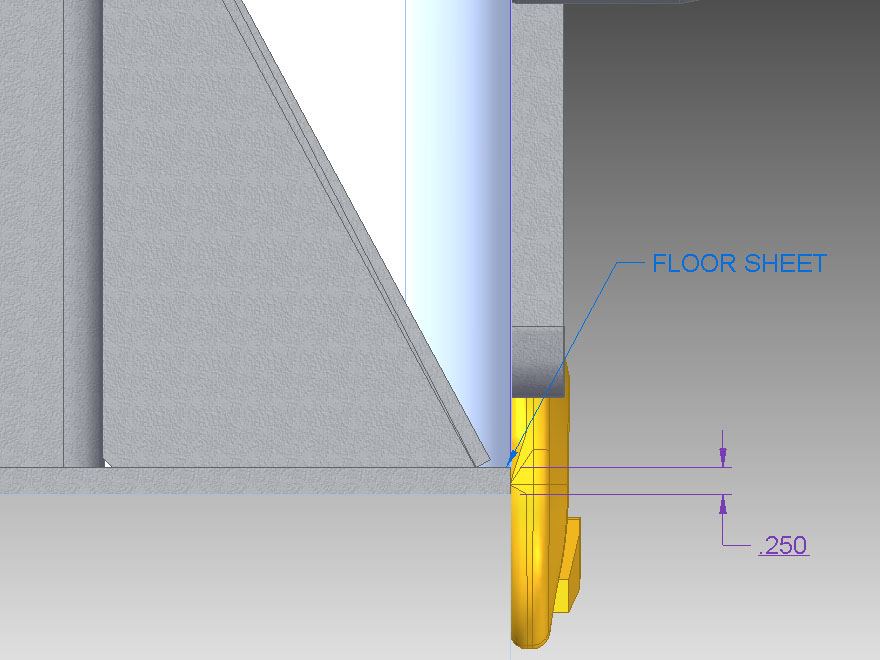

1/4″ Floor Sheet

SCS contractor duty roll off containers feature a heavy duty floor which allows for hauling small excavators, tractors, rock, gravel or concrete.

SCS Drop Forged Hinges

Heavy duty drop forged cast steel door hinges with grease fitting ensures an easy open door.

Available OptionsTell Us Exactly What You Need, We Can Build It

Dump Style Tailgate

SCS contractor duty roll offs are available with a dump style tailgate which provides you with versatility to adapt to changing job requirements.

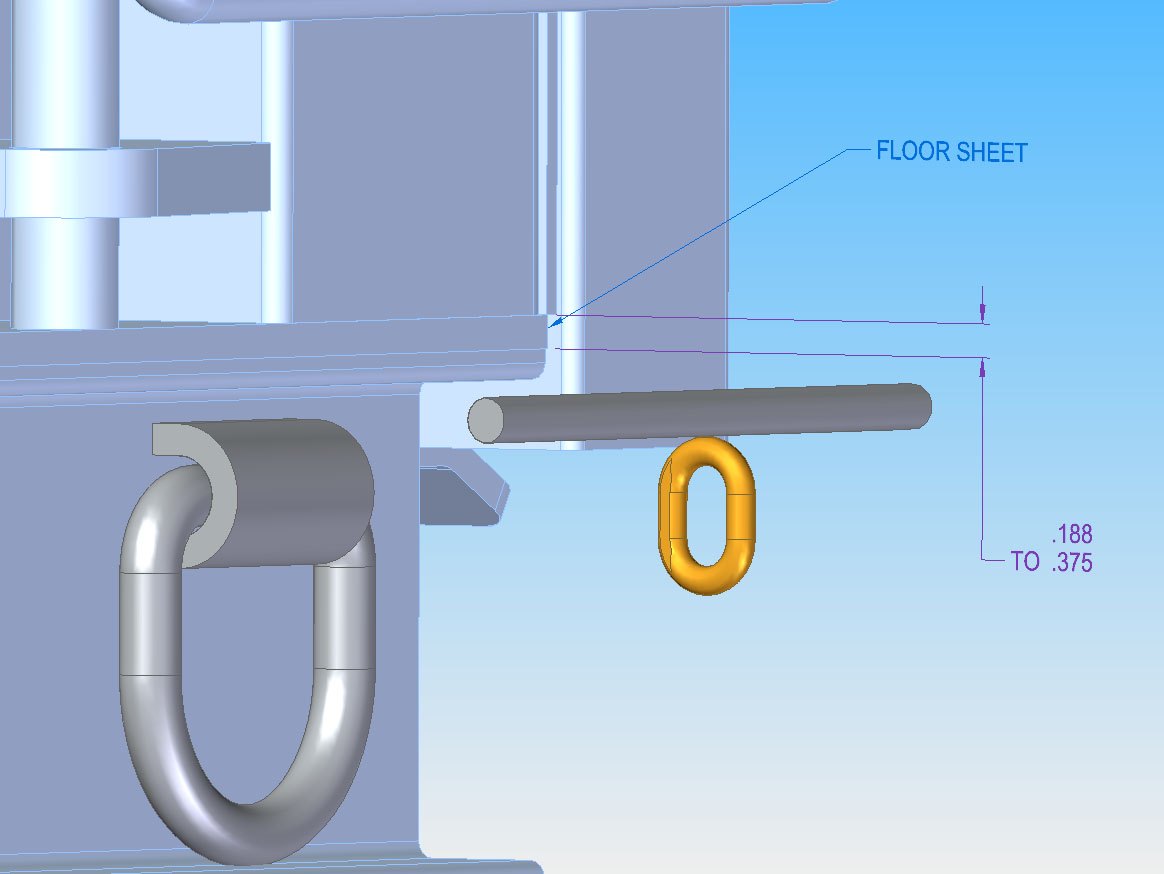

D-Ring Tie Downs

Tailor the bin to your specific application! We offer a heavy duty D-ring tie downs installed to your specification.

Dual Purpose

SCS Roll Off Bins can be fit for any under structure hook lift, cable, live roll, bail hook(Dempster) or dual purpose system.

Heavy Duty Flooring

Increase the strength and durability of your contractor duty container with heavy duty floor options 5/16″ and 3/8″ thick or QT 100 or AR Plate.

Contractor Roll Off Cab Guard

To ensure the safety of your driver and truck, SCS provides a heavy duty cab guard on every dump body we manufacture.

Narrower Widths For Nesting

Our Contractor Duty Roll Off Container widths can be modified for nesting capabilities. Reduce your fuel consumption during transport, by carrying two containers to your job site in one trip.

Full Product SpecificationsNeed More Information? Contact Us At 877-727-7833

- Available in 5 – 17 cubic yard sizes

- Available in 12’ – 20’ lengths

- 3–year parts and labor warranty

- Hook Lift Main rails 6” x 2” x 1/4” steel tube

- Cable Pull Main rails 6” x 2” x 3/16” steel tube

- Cross members 3” x 3” x .120” formed Hi-tensile channel on 18” centers

- Vertical studs 3” x 3” x .120” formed Hi-tensile channel on 18” centers

- Door frame 4″ x 3″ x 3/16″ steel tube

- Walls, door and front sheet 10 GA hot rolled sheet

- Interior and exterior floor to wall support plates, .120” Hi tensile sheet

- Floor 1/4” steel plate

- Rear post – formed 3/16″ Hi-tensile channel

- Front rail 4” x 3” x 3/16” steel tube. 4” x 4” x .250” steel tube on containers over 20’ long

- Side rails 4” x 3” x 3/16” steel tube. 4” x 4” x .250” steel tube on containers over 20’ long

- Landing gear (wheel mount) 6” x 3” x 3/16” Hi-tensile formed channel

- Hinges – Heavy duty dropped forged with grease fitting

- ANSI 245.30-2008 Compliant Latch Options – Carnegie Latch or Turn Buckle Ratchet Latch

- Wheels – 5” standard pipe with 1-1/4” extra heavy pipe hubs and 1-3/16” cold rolled shaft All wheels have full length hubs for axle support and mount to the landing gear cross member with 3/8” formed steel plate

- Welding – Inner floor seams, front and rear wall seams and inside top rail seams are continuous welds

- Two coats of anticorrosive primer on all exterior surfaces

- Two coats of industrial enamel paint in any single color